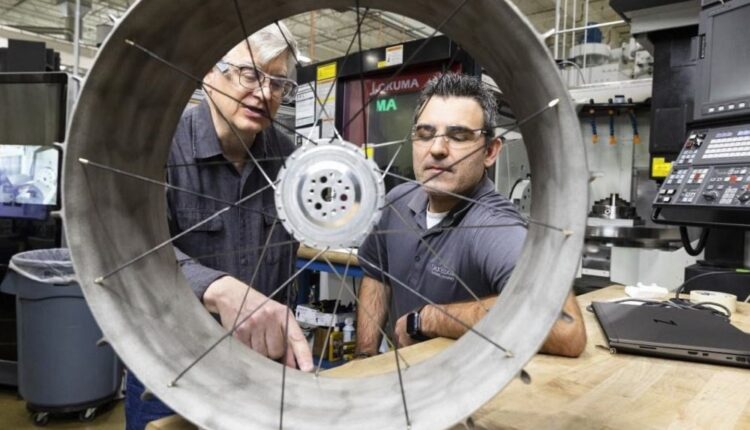

The additively manufactured wheel at Oak Ridge National Laboratory (ORNL) was inspired by the existing lightweight wheels of the Volatile Research Polar Exploration Rover, or VIPER, a mobile robot that NASA plans to send in 2024 to map ice and other resources potentials at the South Pole of the moon. The mission aims to help determine the origin and distribution of the moon’s water and whether enough could be collected from the moon’s surface to sustain the people who live there.

While the 3D-printed wheel prototype won’t actually be used on NASA’s lunar mission, it was created to meet the same design specifications as the wheels manufactured for NASA’s VIPER. Additional testing is planned to validate the design and manufacturing method before using this technology for future lunar or Mars rovers or considering it for other space applications, such as large structural components.

Additive manufacturing can reduce energy use, material waste and lead time, while allowing for design complexity and tailoring of material properties.

In the case of the VIPER wheel, a specialized 3D printer used two coordinated lasers and a rotating build plate to selectively melt metal powder into the designed shape.

Typical metal powder bed systems work in steps: In a cabinet-sized machine, they rake a layer of powder onto a stationary plate. A laser then selectively melts a layer before the plate is lowered slightly, and the process is repeated. The printer used for the rover’s wheel prototype is large enough for a person to fit into and is unique in its ability to print large objects while steps occur simultaneously and continuously, ORNL reported.

Although the machine is unique, a key to the project’s success was the researchers’ experience in process automation and machine control. They used software developed at ORNL to “slice” the wheel design into vertical layers and then balance the workload between the two lasers to print evenly, achieving a high production rate, taking advantage of a recently introduced computational technique for protection of patent.

Source: dpa

(Referential image source: Carlos Jones, ORNL, US Dept. of Energy, Europa Press / dpa)

Visit our news channel on Google News and follow us to get accurate, interesting information and stay up to date with everything. You can also see our daily content on Twitter and Instagram